5 Simple Techniques For machining

Machining is any of various processes through which a piece of Uncooked content is Minimize into a preferred closing condition and sizing by a managed product-elimination course of action. The processes that have this common concept, controlled material removing, are now collectively called subtractive manufacturing,[1] in distinction from processes of managed material addition, which happen to be called additive manufacturing.

Fantastic customer service. I produced a touch upon Instagram about my lever slipping and not tightening... down plus they instantly strike me up, informed me to electronic mail them And they might look after it ASAP.

1a archaic : a created issue irrespective of whether content or immaterial b : conveyance, motor vehicle Particularly : vehicle c archaic : a military services engine d : any of varied apparatuses previously employed to provide stage consequences e(one) : an assemblage (see assemblage perception 1) of areas that transmit forces, movement, and Strength 1 to another within a predetermined fashion (two) : an instrument (for instance a lever) built to transmit or modify the applying of power, power, or movement f : a mechanically, electrically, or electronically operated gadget for carrying out a activity a device for cleaning carpets g : a coin-operated unit a cigarette equipment h : equipment —employed While using the

Considerations To Know About precision machining

C-frame mill They're larger sized, industrial production mills. They feature a knee and stuck spindle head that is only cell vertically. They are typically a great deal more strong than a turret mill, that includes a different hydraulic motor for integral hydraulic energy feeds in all directions, and also a 20 to fifty horsepower motor.

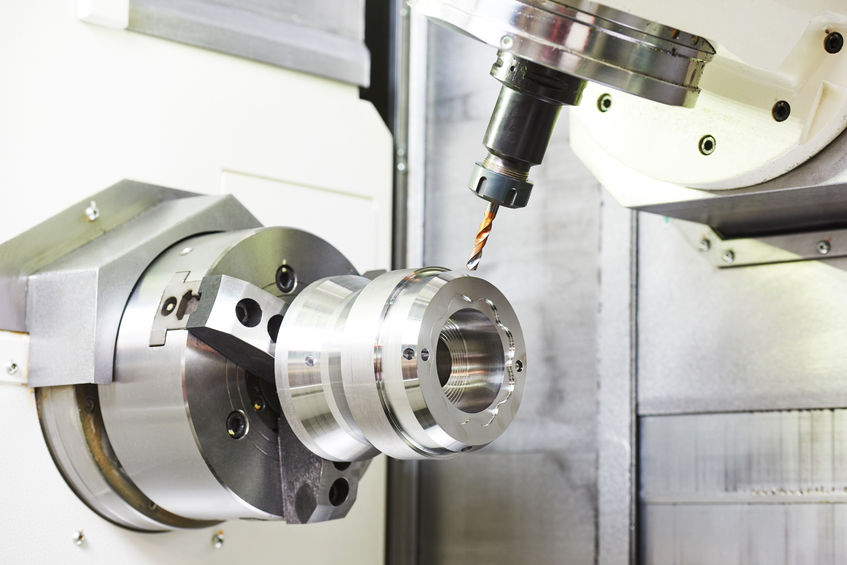

Machining Machining (through the device Instrument and chopping tool) styles metal workpieces. Knowing equally regular and advanced machining methods is significant to overcoming the different dimensional and end difficulties related to mould machining.

Milling is actually a chopping method official source that makes use of a milling cutter to remove content in the area of the workpiece. The milling cutter is usually a rotary chopping Device, typically with numerous slicing points. As opposed to drilling, wherever the Software is advanced together its rotation axis, the cutter in milling is normally moved perpendicular to its axis to make sure that reducing occurs on the circumference in the cutter. Given that the milling cutter enters the workpiece, the cutting edges (flutes or tooth) with the Software repeatedly Lower into and exit from the fabric, shaving off chips (swarf) from the workpiece with Each and every pass.

In these early several years, milling was normally seen as only a roughing operation to get followed by finishing with a hand file. The idea of decreasing hand filing was much more significant than replacing it. 1840s–1860[edit]

By 1940, automation by means of cams, including in screw equipment and automated chuckers, had previously been very perfectly formulated for decades. Beginning from the 1930s, Concepts involving servomechanisms were from the air, but it absolutely was Specially throughout and right away soon after Entire world War II which they started to germinate (see also Numerical control > History). These have been before long combined with the rising know-how of electronic desktops. This technological improvement milieu, spanning from your fast pre–Globe War II time period in to the fifties, was run because of the navy capital expenses that pursued up to date breakthroughs from the directing of gun and rocket artillery and in missile advice—other apps wherein human beings wished to manage the kinematics/dynamics of large devices rapidly, specifically, and routinely.

Top precision machining Secrets

one : a device with relocating pieces that does some wished-for work when it is provided with ability a sewing device

Regardless of whether for smaller, extremely-precise pieces – or the finest surgical instruments, components and implants – partnering with Orchid will bring about the best production remedies executed inside the shortest possible time for the lowest total Price.

Machining operations commonly divide into two types, distinguished by goal and reducing ailments:

Normally a final go which has a slow feed charge is accustomed to improve the area finish after the bulk of the fabric continues to be removed.. In a specific experience milling operation, the revolution marks will only be microscopic scratches on account of imperfections inside the cutting edge.

Indicators on precision machining You Should Know

Pair-clever intersection technique:In pair-sensible intersection solution, the boundary of your pocket is brought inwards in steps, The offset segments will intersect at concave corners. To get the necessary contour, these intersections are to become trimmed off.